|

item |

argument |

|

Storage type |

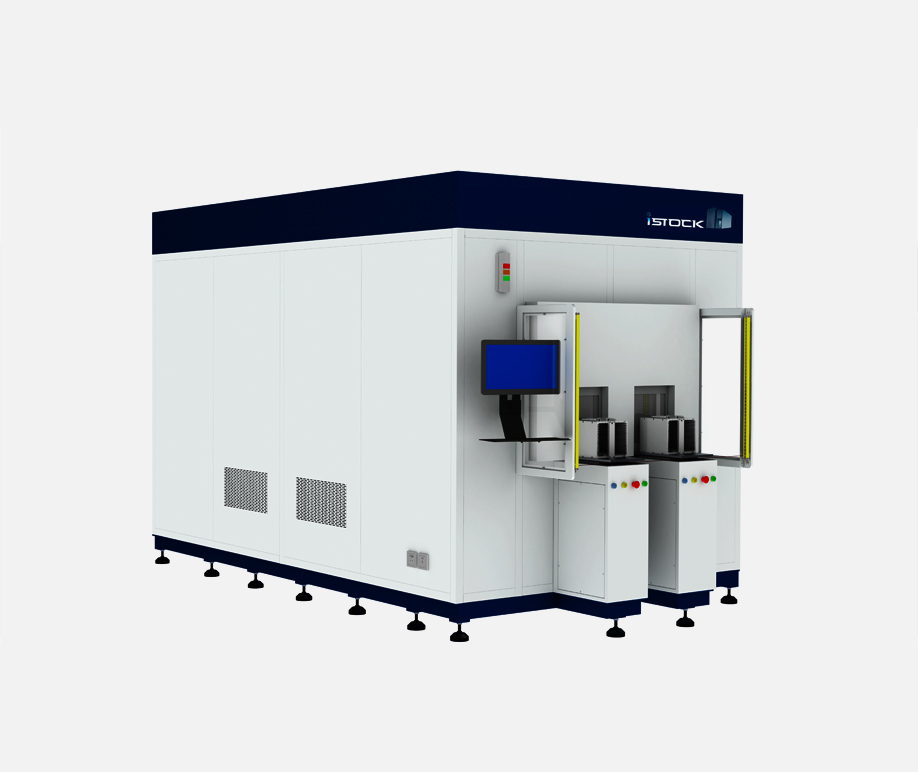

i-Stock Semi Magazine stocker |

|

External dimension |

L5300*W2200*H3100mm (customizable) |

|

Material type |

Die, Lead frame and other materials |

|

wafer specification |

L300*W195*H160mm (customizable) |

|

Storage capacity |

196boxes |

|

Arm load |

12-25kg (customizable) |

|

Positioning accuracy |

0.1-0.3mm |

|

Save/take time |

20-30s/box |

|

Purification class |

class10;100;1000 |

|

Vibration |

≤0.5G |

|

noise |

≤75DB |

|

UPS |

After power off half an hour for the industrial computer to upload information, the operating system shut down normally |

|

Communication mode |

SECS/GEM (E82/E88) |

|

Electrostatic protection |

Anti-static treatment material storage, surface resistance value106-1011Ω |

|

Temperature and humidity control range |

Control range: Temperature 20-25°C, relative humidity 10-45%RH |

|

EFEM |

It can connect to AMR/OHT |

One thing, one yard, one storage place "to achieve unmanned,

Accurate and intelligent management

Double manipulator cooperative operation, higher efficiency in and out of the warehouse picking,

Automatic bulk material access

Improve material picking accuracy and accuracy,

Reduce labor intensity and artificial wafer loss

Equipped with FFU, it meets the requirements of semiconductor workshop cleanliness level

A variety of inbound and outbound docking modes, calmly cope with various scenarios

Conveying needs of the same material

Customized intelligent Kanban, intelligent data visible