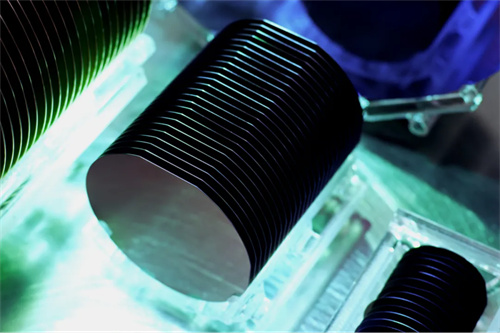

Semiconductor wafer manufacturing is a highly complex process involving multiple processes and equipment. Wafers need to be stored, transferred and processed in different processes, and semiconductor wafer intelligent warehousing can help manage these wafers to ensure that they are handled correctly throughout the production process.

And semiconductor wafer manufacturing for the production environment requirements are very strict, including temperature, humidity, cleanliness and other aspects. Intelligent storage of semiconductor wafers provides a controlled environment to protect wafers from the external environment and ensure the stability and reliability of the manufacturing process.

Semiconductor wafer smart warehousing also makes efficient use of space by centralizing wafer storage and processing in one device, saving space on the production line. In addition, through automated control and management, labor costs can be reduced and production efficiency improved, thereby reducing production costs.

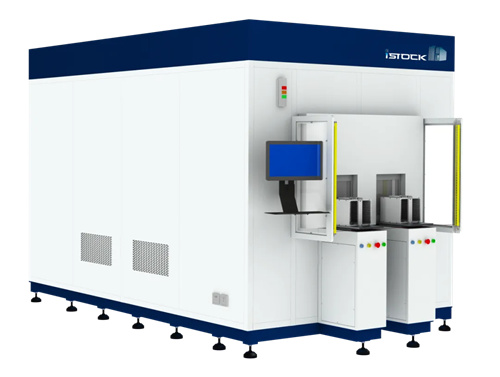

Open up the material flow and information flow between different process flows and software information, realize the automatic transfer or automatic loading and unloading of wafer materials in each workshop and machine, and solve the problem of inefficiency and low product defect rate caused by manual work. Enabling semiconductor wafer warehouse and storage process equipment, intelligent, unmanned, improve work efficiency, reduce inventory, achieve the highest value of materials, standardize management, so as to reduce business operating costs as their own responsibility.

Set up the ability to dominate the potential

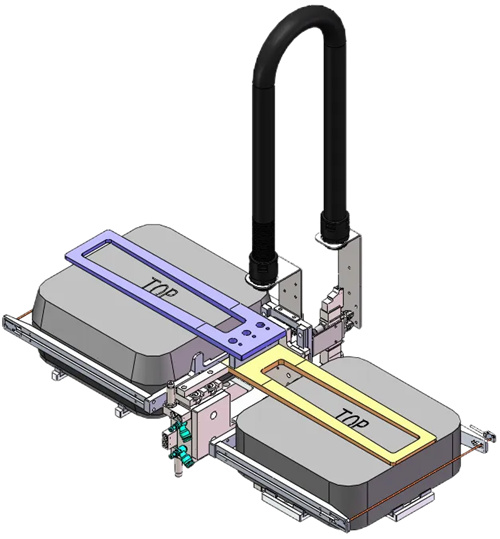

Intelligent clamping: The combination of visual recognition and motion planning ensures the accuracy and stability of the clamping action.

Efficient production: Improve production efficiency, reduce manual operation, reduce error rate, and realize intelligent production management.

Precise operation: Through the intelligent storage system, precise clamping and processing of wafers can be achieved to improve production quality.

Cost savings: Reduce labor costs, reduce operational errors, improve production efficiency, and bring long-term cost savings.

I-stock has always adhered to the customer needs as the core, driven by intelligent equipment, precision technology, industrial software to open up data flow, data +AI algorithm to empower the electronics and semiconductor industry intelligent storage, focus on product quality, heart service.I-stock helps enterprises solve the practical problems encountered in the scientific, standardized, digitized, automated and intelligent upgrading of the intelligent storage field, and provides customized services for intelligent storage equipment. In the future, I-stock will continue to play the advantages of technical talents and resources to contribute to the transformation and upgrading of China's manufacturing industry. In this process, I-stock will help more enterprises enter the lighthouse factory, and work together to promote China's manufacturing industry to the top of the global value chain.