Semiconductor wafer adsorption technology is a technique used to fix and hold wafers in the semiconductor manufacturing process. It is commonly used during processing, such as coating, exposure, etching and cleaning steps, to ensure the position and stability of the wafer.

VACUUM CHUCK:

Vacuum sucker is a common wafer adsorption technology. It uses vacuum adsorption force to hold the wafer to the machine. Vacuum suckers are usually composed of multiple small holes, and by creating a vacuum inside the hole, the adsorption force is formed.

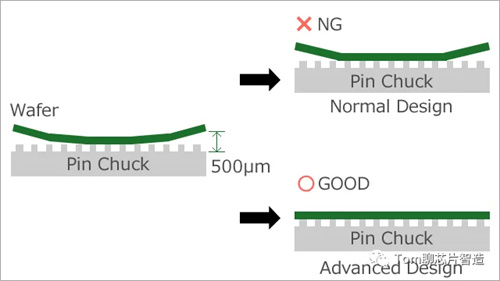

1. Reliability: Mechanical vacuum adsorption provides a stable adsorption force, which can ensure the stability of the wafer during processing.

2. Versatility: This method is suitable for different sizes and types of wafers, and has high flexibility.

3. Simple maintenance: Mechanical vacuum adsorption system is easier to maintain.

1. Potential damage risk: If the vacuum fails or is operated improperly, the wafer may be damaged.

2. Sensitivity: For extremely fragile or ultra-thin wafers, mechanical vacuum adsorption may not be the best choice.

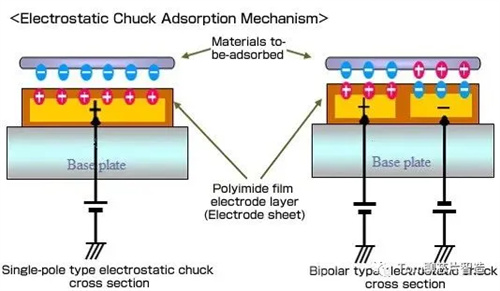

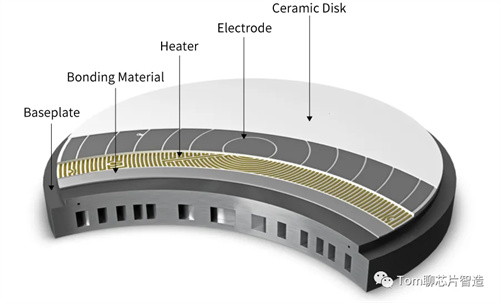

1. No physical contact: Electrostatic adsorption does not require physical contact with the wafer, thus reducing the risk of mechanical damage and wafer rupture.

2. High positioning accuracy: electrostatic adsorption can accurately control the position of the wafer to ensure the stability of the wafer during processing.

3. Strong anti-interference ability: electrostatic adsorption is less affected by external environmental factors.

1. High equipment cost: Compared with mechanical vacuum adsorption, electrostatic adsorption equipment cost is higher.

2. Limited adsorption range: Electrostatic adsorption is suitable for specific sizes and types of wafers.

3. Complex maintenance: The electrostatic adsorption system needs regular inspection and maintenance to ensure its normal operation.

Magnetic cups are a technology that uses magnetic forces to hold wafers to a machine. It creates an adsorption force by creating a magnetic field between the wafer and the machine. Magnetic sucker is usually composed of permanent magnet and magnetic material, by adjusting the magnetic field strength and distribution to control the adsorption force.

Advantages:

1. Non-contact adsorption: Compared with mechanical clamping, magnetic suction cups do not need direct contact when adsorbing wafers, reducing the risk of damage to the wafer surface.

2. Stable adsorption force: The magnetic field generated by the magnetic sucker can provide a stable adsorption force, which is conducive to keeping the position of the wafer stable during operation.

3. Suitable for a variety of sizes and shapes of wafers: magnetic suction cups can be adapted to different sizes and shapes of wafers, with high versatility.

4. Easy operation: The magnetic sucker is easy to operate and can improve production efficiency.

5. High degree of automation: In combination with robots and other automation equipment, the automatic handling and processing of wafers can be realized.

Cons:

1. High equipment cost: The cost of magnetic suction cup equipment is higher than that of other adsorption methods (such as suction cups), especially in mass production.

2. Magnetic field interference: The magnetic field generated by the magnetic chuck may interfere with the surrounding electronic equipment and affect the normal operation of other equipment.

3. Wafer damage risk: In the process of wafer adsorption and release, excessive stress may be caused to the local wafer due to uneven magnetic field or improper operation, thus damaging the wafer surface.

4. Maintenance costs: The magnetic chuck equipment needs regular maintenance and overhaul to ensure its normal operation.

5. Limit the thickness of the wafer: The magnetic sucker has a certain limit on the thickness of the wafer, and other adsorption methods may be required for thicker wafers.

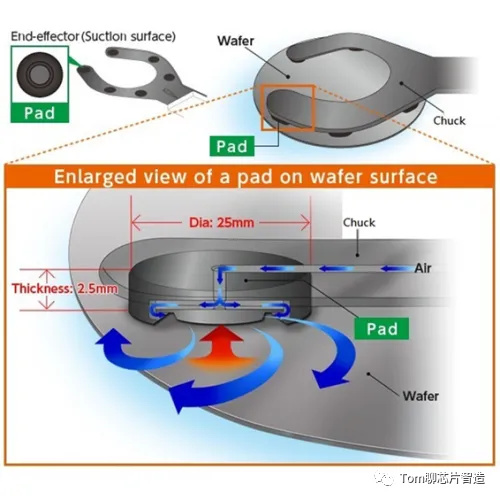

1. Air generation: Compressed air is introduced into the suction cup through the air supply system inside the suction cup.

2. Airflow acceleration: The airflow passes through the nozzle or nozzle hole of the sucker to accelerate the flow.

3. Formation of low pressure area: The acceleration of air flow causes the surrounding pressure to decrease, forming a low pressure area.

4. Adsorption force generation: When the object is placed on the suction cup, the air flow in the low pressure area adsorbs the object to the surface of the suction cup.

Advantages of Bernoulli suckers:

1. No contact: Bernoulli suction cups do not require physical contact with objects, reducing the risk of damage and breakage of objects.

2. Wide range of application: Bernoulli suction cups are suitable for objects of various shapes and materials, such as flat, curved, fragile objects, etc.

3. Fast operation: The adsorption and release speed of Bernoulli sucker is fast, which is suitable for efficient automated operation.

Disadvantages of Bernoulli sucker:

1. Limited adsorption power: The adsorption power of Bernoulli sucker is relatively low, and may not be suitable for heavy objects or situations requiring large adsorption power.

2. Sensitive to the environment: Bernoulli sucker has a great impact on the environment, such as the speed of the air flow, temperature and humidity and other factors may affect the adsorption effect.

3. Not suitable for scenes with high sealing requirements: Due to the existence of air flow, Bernoulli suction cups are not suitable for scenes with high sealing requirements for objects.

I-stock helps enterprises solve the practical problems encountered in the scientific, standardized, digitized, automated and intelligent upgrading of the intelligent storage field, and provides customized services for intelligent storage equipment.

In the future, I-stock will continue to play the advantages of technical talents and resources to contribute to the transformation and upgrading of China's manufacturing industry. In this process, I-stock will help more enterprises enter the lighthouse factory, and work together to promote China's manufacturing industry to the top of the global value chain.

(Some of the images are quoted in "Tom talks about chip intelligence")